Quantum advances rely on the production of nanoscale wires that are based on several state-of-the-art nanolithographic technologies, to develop wires via bottom-up synthesis. However, a critical challenge is to grow uniform atomic crystalline wires and construct network structures to build nanocircuits.

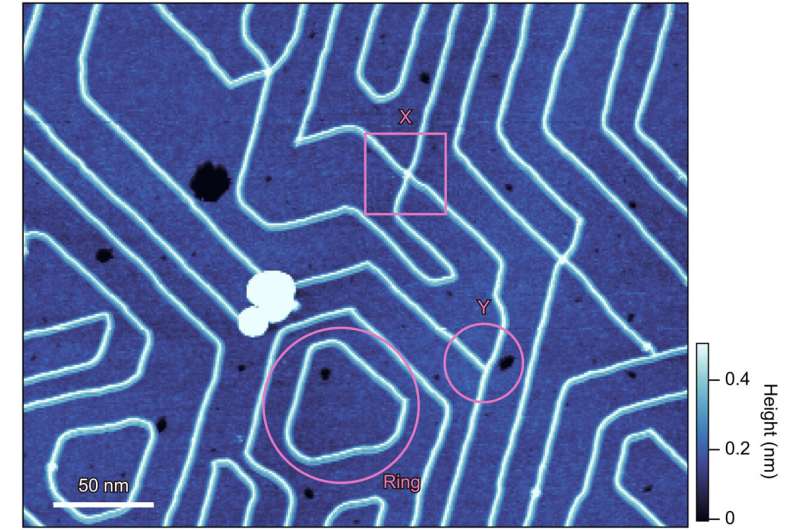

In a new report in Science Advances, Tomoya Asaba and a team of researchers in physics and materials science at the Kyoto University, the University of Tokyo in Japan, and the Institute of Theoretical Physics in Germany, discovered a simple method to develop atomic-scale wires in the shape of nano-rings, stripes and X-/Y- junctions.

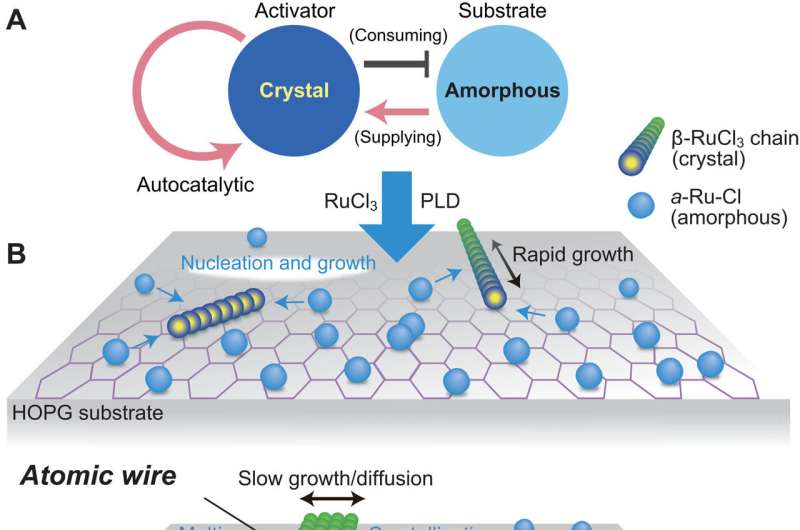

Using pulsed-laser-deposition, the physicists and materials scientists grew single crystalline, atomic-scale wires of a Mott insulator, which maintained a bandgap comparable to wide-gap semiconductors. Such wires were a unit cell in thickness and a few microns in length. The researchers observed atomic pattern formation through non-equilibrium reaction-diffusion processes to offer a hitherto unknown perspective on the phenomena of atomic-scale self-organization to gain insight to the formation of quantum architecture in nano-networks.

New methods to engineer atomic-scale nanowires

The basic features of most technical devices change when their dimensions are reduced. When a device is reduced to the nanoscale, the fabrication and integration of one-dimensional wire patterns become increasingly complex. Developing top-down approaches with large-scale equipment such as electron beam and focused ion beam lithography to include nanowires with a thickness and width less than 10 nanometers is another technical challenge.

Similarly, bottom-up technologies that use self-assembly processes cannot effectively determine the uniformity of the wires either. During bottom-up engineering, nanowire array integration depends on two complicated steps of growing randomly oriented nanowires first, and then aligning them into an array; therefore, this calls for a new approach to fabricate uniform, atomic-scale wires, and engineer nanopatterns.

In this work, Asaba and colleagues engineered uniform and long, single-crystalline wires of ruthenium trichloride (RuCl3) at the atomic scale via a simple deposition method. They manufactured several characteristic patterns necessary to realize quantum nanocircuits including atomically smooth junctions and nanorings. The ruthenium trichloride material is interesting as a Mott insulator where electron-electron interactions open an energy gap. The team formed and integrated the nanowire patterns as part of a thin-film growth process, thereby diverging from the conventional method behind atomic scale wire patterns—to promote self-organization instead.

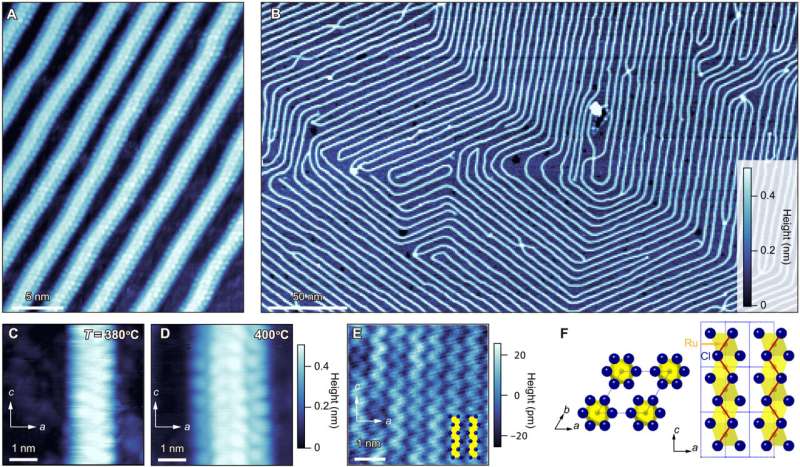

Engineering nanocircuits

During the experiments, the team melted the ruthenium trichloride on highly oriented pyrolytic graphite surfaces by using pulsed-laser-deposition and observed the outcome with scanning tunneling microscopy. They obtained an atomic-resolution image of a sample grown at intense deposition temperatures to detect a surface covered by a unique pattern of wires. While each wire consisted of periodically spaced atoms, they noted a single crystalline structure. The materials scientists then studied the material forming the atomic-scale wires by extending the deposition time to grow a two-dimensional monolayer and thicker films and verified its composition to be crystallized ruthenium trichloride.

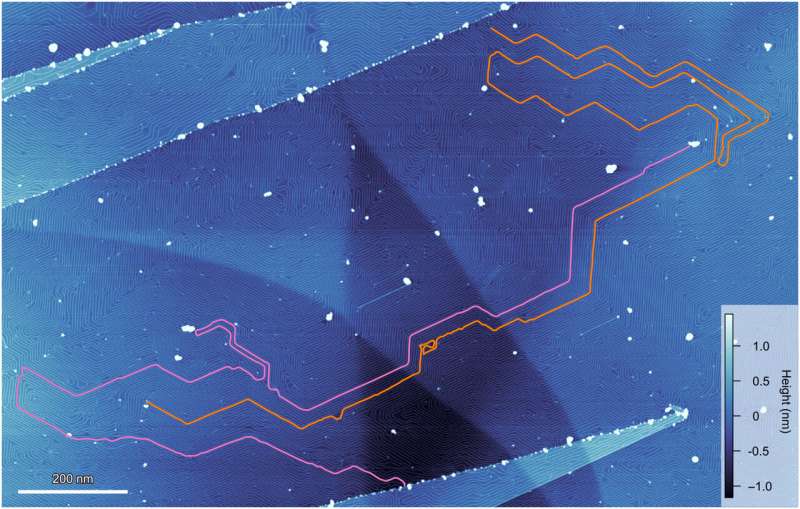

The atomic wires maintained a length exceeding 3 micrometers as a unique and unprecedented feature. They also contained two or four ruthenium trichloride single crystalline chains growing on pyrolytic graphite surfaces. In its constitution, the wires consisted of quadrupole chains of the material at first, which later reduced to double chains with decreasing temperatures to form atomically smooth junctions and rings without defects and clusters to eventually engineer the nanocircuits.

Characterizing the nanocircuits

The materials scientists next studied the electronic structure of the materials by measuring differential tunneling conductance, and compared the outcomes with various forms of the material and pyrolytic graphite surfaces. They noted clear energetic gaps in ruthenium trichloride, indicative of semiconducting or insulating electronic structures.

They unveiled the origin of the energy gap through systematic band calculations of variant forms of ruthenium trichloride materials, including a two-chain wire and its monolayer, and bulk forms, to observe electron correlations and spin-orbit interactions. The material eventually revealed an open energy gap at the Fermi energy across all experimental constructs used in the study to confirm the material as a Mott insulator.

![Stripe patterns of β-RuCl3 atomic-scale wires. (A to D) Topographic images of β-RuCl3 wires with four–unit cell width grown at 400°C. By changing the deposition time of the laser from one to five shots, the wire distance can be tuned from much longer than 10 nm (A) to shorter than 2 nm (D). The power of the laser pulse is further attenuated to 60% for (A). The color scale is shared by (A) to (D). (E) A topographic image of a β-RuCl3 monolayer thin film grown by a further increase of the deposition time to 20 shots. Green and white regions correspond to mono- and double-layer thick β-RuCl3, respectively. No 1D wire pattern is observed. The setpoint conditions are 20 pA and 3 V [(A), (B), and (E)] and 30 pA and 3 V [(C) and (D)]. (F) Line profiles of fast Fourier transform (FFT) images in the direction of peaks corresponding to the wire repetition. The curves are vertically shifted for clarity. (G) The periodicity (the inverse of the wave number) is plotted as a function of the number of pulses. The dashed gray line indicates the width of the four-chain wire. The data point for the 20 shots represents the lateral lattice constant of monolayer β-RuCl3. Credit: Science Advances (2023). DOI: 10.1126/sciadv.abq5561 Engineering self-integrated atomic quantum wires to form nano-networks](https://scx1.b-cdn.net/csz/news/800a/2023/engineering-self-integ-3.jpg)

Mechanisms of pattern formation

The team credited the formation of the nanowire array to thin-film growth that differed from any process hitherto known. Aside from stripe patterns observed during the experiments, the team discussed the mechanisms underlying pattern formation and the emergence of several distinct characteristic features. According to the patterns, static interactions were not the driving force of the atomic-wire array.

Instead, they credited the feature to non-equilibrium reaction-diffusion processes. Since scanning tunneling microscopy was too slow to capture the dynamic processes of thin-film growth, the team expect to conduct direct measurements of the dynamic process at the atomic scale to fully understand the growth mechanism.

Outlook

In this way, Tomoya Asaba and colleagues assumed reaction-diffusion mechanisms to stimulate the origin of pattern formation in atomic wires, leading to the manifestation of stripe patterns via Turing instability. The feature contributed to the spontaneous emergence of spatially periodic patterns.

The nanowires and junctions dramatically increased the integration of electronic circuits, to provide a physical playground to explore the phenomenon of atomic-scale-based, non-equilibrium self-organization suited for exotic electronic states and for quantum advances.

More information:

Tomoya Asaba et al, Growth of self-integrated atomic quantum wires and junctions of a Mott semiconductor, Science Advances (2023). DOI: 10.1126/sciadv.abq5561

Junhao Lin et al, Flexible metallic nanowires with self-adaptive contacts to semiconducting transition-metal dichalcogenide monolayers, Nature Nanotechnology (2014). DOI: 10.1038/nnano.2014.81

Journal information:

Nature Nanotechnology

,

Science Advances